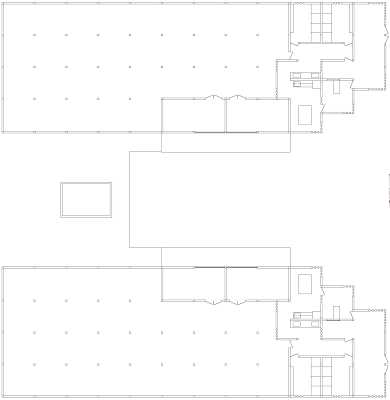

The factories are split up by starch in one building and alcohol in another. In between the two factory buildings you can see a power house and a loading dock.

There is a lobby, changing room, bathroom, office, lounge, and wash up area in each building, as required for each of the factories.

Since the tubers only last a day or two after they've been harvested before they begin deteriorating, the tubers have to be produced into the product the same day they are harvested.

There are two refrigerated storage units, one for the newly picked, peeled and washed tubers, and one for the finished product. They are easily accessible from the outside, in the loading dock area. The one holding the unfinished tubers will only be refrigerated during the day, by the end of the day, all tubers must be used up, so the refrigerator can be shut off over night.

from left to right in the section is the lounge, the wash area (and door into the factory space), and the locker and lavatory room.